When in 2014 Granma investigated the production of containers and packaging in the country, certain figures stood out, especially those related to imports.

It was said, for example, that more than 22 million USD were allocated for the purchase in international markets of flexible packaging, that is, the plastic casings in which spaghetti, coffee, yogurt, soaps and other goods are placed, as well as another 10 million USD for labels.

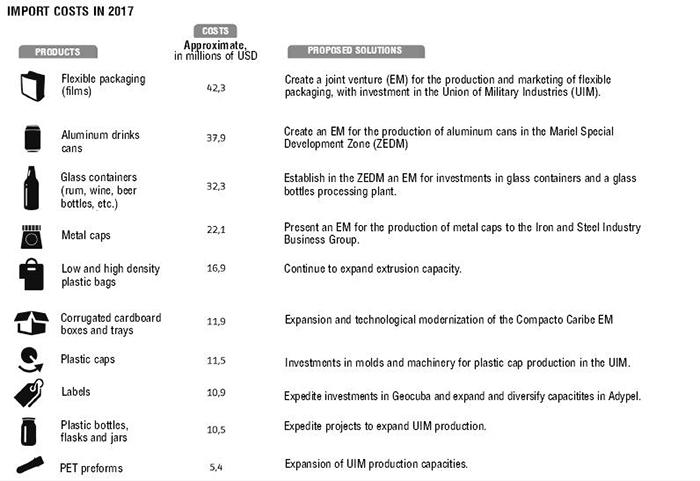

In 2018, the figures continue to demand second readings. In 2017, the country spent more than 42 million USD on these “little bags”, and almost 11 million more on labeling.

Similar to what was reported then, drink cans, glass bottles, corrugated cardboard boxes, high and low density bags, and metal caps, are among the group of ten imported items to which 80% of the more than 266 million dollars spent in this area in 2017 were allocated.

Back in 2014, investments were underway to reduce or end the need for purchases of aluminum cans, glass and flexible packaging (films) and containers in international markets, to mention just some of the products that figure among the major import costs to the island. Efforts continue in this field today, and have shown some progress.

New investment projects have been incorporated, and some have even been concluded and are already bearing fruit, such as the plant for the manufacture of egg trays, which allowed demand to be met in 2017, with no imports of this item planned for 2018.

Also recognized four years ago was the non-implementation of investment plans, due to delays in the preparation of feasibility studies and failure to identify financial sources or external partners to materialize projects, as the main limitation to the development of the national packaging industry.

In the 2017 annual work report, the Directorate of Packaging and Containers of the Ministry of Industries (Mindus) incorporated a paragraph with almost identical words to the previous, or what is the same, with almost identical problems identified.

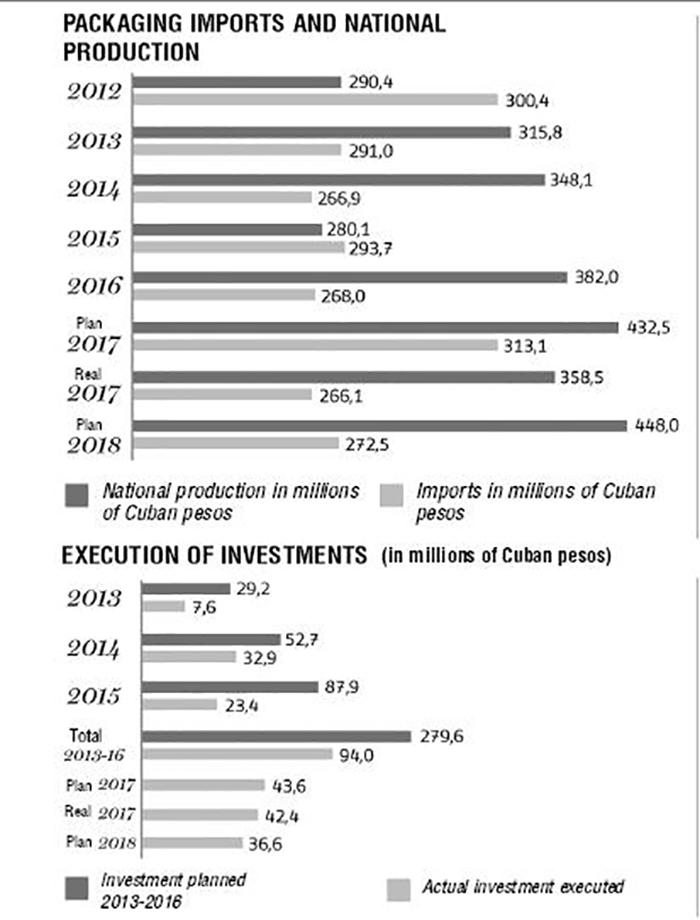

However, although this analysis makes clear how much remains to be done to satisfy increasing demand, it by no means ignores the growing production of packaging in the country, a trend maintained in recent years, following the approval, in March 2013, of the policy for the development of this area.

According to Yamilín González Milián, Mindus deputy director of Packaging and Containers, national industry production in 2017 grew by 26% compared to the previous year, and investments also increased, to reach in the order of 42.4 million pesos.

The Packaging and Containers Center was also created, a basic enterprise unit (UEB) that will be dedicated to the evaluation of raw materials, and to following and incorporating the most innovative global trends, in accordance with our possibilities

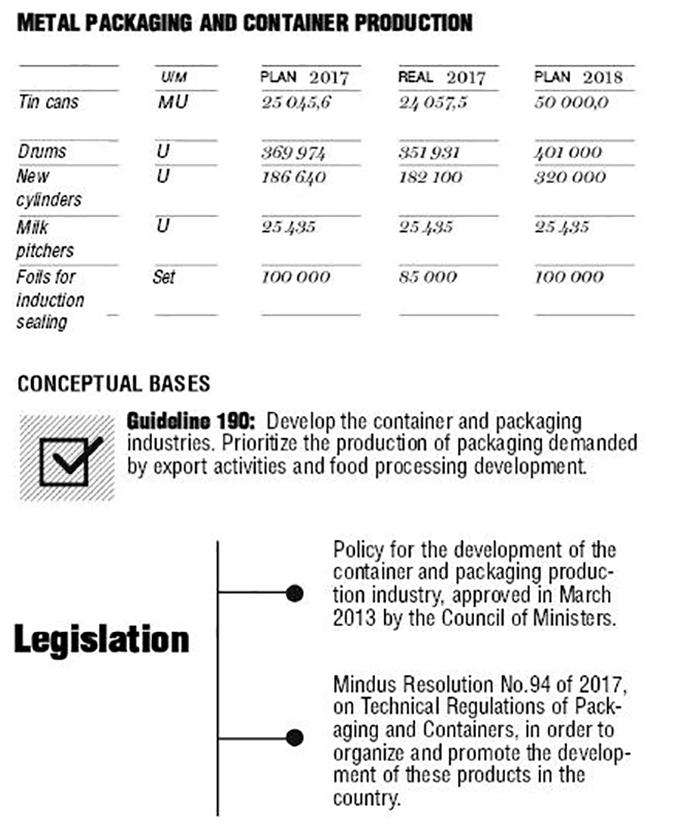

Regarding legislation, it is worth highlighting the approval in 2017 of Mindus Resolution No. 94 on Technical Regulations of Packaging and Containers, which in both letter and spirit standardizes the systems of making and using these products in Cuba.

ADVANCES STEP BY STEP

The principles of the island’s packaging policy, approved in 2013, based on a comprehensive vision, promote the manufacture of items destined for the export and food processing sectors, the sale of construction materials, as well as the progressive substitution of imports.

Since their approval, these guidelines have not changed. They set the norms for what was done in the previous year and what will be done over the course of 2018.

According to González, the supply of packaging in 2017 (combining national production and imports) exceeded 620 million pesos, and for this year, despite financial restrictions, some 721 million are expected.

The numbers, she added, also show increased exploitation of productive capacities, mainly in paper, cardboard, and plastic containers. In this sense, the national industry has planned manufacturing of 448 million pesos in 2018, which would satisfy 62% of the solvent demand (that is, the demand included within the plan, as the real demand is far removed from these numbers).

In order to bring plans increasingly into line with real industry performance, according to Juana Iris Herrera Fuentes, specialist of the Mindus Containers and Packaging Directorate, the 2018 plan was also supported by an analysis of the fresh fruits and vegetables to be processed in the country.

After this assessment, she stressed, it was possible to ensure the production of small-format containers for 82% of the planned finished products in this sector. The rest, equivalent to about 18,000 tons of processed fruits and vegetables, will be sold in bulk to the population, an alternative that requires actions that guarantee the timely arrival of the product to sales points.

However, the tomato harvest, for example, has been less productive than was envisaged.

According to Herrera, 2018 will also see emphasis on the reuse of plastic, steel and glass containers, a practice that must consider the relevant procedures. Forecasts include some 113 million glass containers and 15 million polypropylene bags, although the strategy seeks to continue identifying further possibilities for reuse.

At the beginning of each year, or new stage, it is almost mandatory to identify new challenges. In this regard, Yamilín González returns to an aspect that can not be postponed: identifying and strengthening investments and joint ventures that technologically and financially support the development of the national industry.

Within this large group, we already know where the emphasis will be on joint venture projects that contribute to the manufacture of aluminum cans, flexible packaging and glass containers, the same that despite efforts over years have not materialized.

TIN MAKES ITS MARK

The biggest increases in national production in 2018 were in tin containers, although levels are still not enough to satisfy all demand.

This was one of the priority issues analyzed in the National Assembly of People’s Power sessions last December, considering the constantly increasing demand, especially in the food and agriculture sectors, and the impossibility of the national industry to meet their needs.

Nelly Toirac Castaño, director general of the Metal Packaging and Containers Enterprise (Envametal), explains that for this year, the figure demanded is 64 million tin cans.

With all hopes pinned on investment underway at the Luis Melián production workshop, part of the Envases Occidente (Envocc) factory, the plan foresees the production of 50 million cans, a figure that, although not covering the total need, would duplicate what was produced in 2017.

The investment process, amounting to 240,000 euros, consists, on the one hand, of the assembly of a palletizer that will increase production capacities; and on the other, the training of personnel that will operate this machinery and work along the rest of the production line.

If the planned schedules are met, Toirac notes, results will be noticeable beginning in April, a date that, according to experts, will be tense for the industry in terms of meeting annual plans.

According to Envocc Director Sergio Medero Santana, “The palletizer installed today is manual; it requires two operators and palletizes 160 containers per minute. The new one is semi-automatic, requires one operator and processes 400 containers per minute.” The substantial productive benefit is evident.

However, the figures achieved in January, even without this investment, mitigate to some extent the productive challenge of 2018. “With the new machinery, we project the manufacture of 4.7 million containers per month. However, under the current conditions we managed to make 3.7 million, a record.”

But together with the motivation of workers, who from April will be distributed in three eight-hour shifts, in the opinion of Toirac it is necessary to have “financial stability that allows payment to the main suppliers of raw materials abroad,” an issue that in 2017 resulted in the non-compliance with planned production levels.

“We must also work with national enterprises to guarantee supplies, which have also failed. This is an issue monitored daily by managers, to anticipate setbacks and plan solutions, because what fails to be produced is not recovered.”

This view is shared by Daymel Pérez González, director of the Luis Melián workshop, who notes, “This productive commitment implies greater responsibility, working with coverage that exceeds the quarter, increasing supervision and control, reducing shrinkage rates... Bear in mind that about 98% of our production is state orders.”

QUALITY, A CONSTANT CONCERN

In the Luis Melián workshop, there are currently two production lines for cylindrical containers, in eight formats. Investments were made in 2008 and 2012, focused on improving technology, increasing production levels and promoting quality, with the incorporation of electric welding.

In fact, there is only one workshop in Cuba, the Armando Mirabal, which still uses lead-tin welding. A joint venture project is already planned that will modify the technology and allow for the manufacturing of paint cans, which are not currently produced in the country.

However, quality does not only depend on the technology, but also on machine operators, already accustomed to detecting faults. There is no detail that can escape mechanics Julio Alonso and Raúl Hernández, with 25 and 38 years of experience, respectively. The same goes for Lázaro Mario García, quality control technician, who every half hour reviews the dimensions of the cans.

“You really have to stick by the machines. If they make 400 containers per minute and you take two to discover a flaw, imagine how many containers are lost,” he states as he hurriedly heads back toward the production line.